Save valuable time and costs with RFID (Radio Frequency Identification) solutions from TEC-RFID, with a carefully crafted bespoke service for your logistics company. RFID technology offers versatile features that can be employed to extensively improve the safety, security and efficiency of the distribution and transportation of goods, as well as in the logistics of the supply chain. This innovative technology enables companies to effectively manage the supply chain with unprecedented levels of automation that lead to a better degree of control for all.

The Challenges in Traditional Logistics

Many companies specialising in logistics face daily challenges due to outdated technology and processes that TEC-RFID can help enhance and optimise.

Many of the challenges in traditional logistics include:

Inventory Management:

Manual inventory management is common in traditional logistics. Human error is possible while manually tracking inventories, orders and deliveries. Miscounts, data entry errors and lost items cause inaccurate inventory records. These errors cause stockouts, overstocking, lost revenue and higher carrying costs.

Manual inventory management also takes up valuable time which could be spent in other areas of business.

Supply Chain Visibility:

Traditional logistics systems often lack real-time data and transparency, making it difficult for organisations to understand their supply chain operations. Lack of visibility delays supply chain identification and demand forecasting as well as causes issues when managing lead times.

Asset Tracking and Management:

Tracking and managing assets across several locations and stages in the supply chain is challenging without RFID technology in logistics. With barcode tracking, each item needs to be scanned individually. With RFID, you can track assets going through choke points automatically, or scan hundreds of items per second using a handheld reader. GPS trackers can also track valuable assets no matter where they are in the world.

Benefits of RFID in Logistics

The RFID Solution

RFID in logistics management has had a huge impact, continuing to evolve as a more reliable and efficient tracking system that improves the process of monitoring inventory accuracy and optimising warehouse space as well as many other benefits.

How RFID Works

RFID Readers can be placed at various checkpoints throughout the supply chain, from the production line to the shipping dock – all designed to keep track of items as they move through the system.

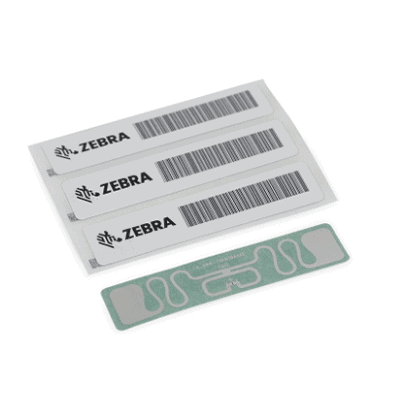

RFID Tags can be attached to or implanted in products, pallets, cases or items being shipped. The tag sends a signal to an RFID reader, which can then determine the location of the product and track it throughout the supply chain.

RFID is used in warehouses to improve the overall inventory management. RFID can be used to track the location of individual items in a warehouse, helping to reduce lost or misplaced items. Implementing an RFID logistics tracking system automates tasks such as stocktaking and order fulfilment. Finally, RFID can improve warehouse efficiency by preventing overcrowding of shelves and helping to ensure goods are placed in the correct location.

Real-Time Visibility:

RFID provides real-time information on stock levels, item location and order status so goods can be expedited as needed.

Accuracy and Efficiency:

With automated stock checks, the reduction of human error is enhanced, helping to streamline operations, ultimately leading to cost savings and improved operational efficiency.

Scalability:

TEC-RFID can scale our RFID solutions to your logistics operations and the technology can easily be adapted as your business grows. This is the ultimate choice for all different sizes of logistics organisations.

Compliance and Reporting:

RFID ensures regulatory compliance in the logistics industry by providing precise, real-time data on production processes, material sourcing and product handling. Additionally, it simplifies the reporting process by automating data collection and record keeping. The transparency that RFID offers in logistics management solutions is unrivalled and helps to alleviate the strains on the ever-changing global supply chain.

Why Choose Us?

Expertise and Experience:

TEC-RFID is a UK-based company that has extensive experience helping logistics organisations optimise their operations using RFID.

Customised Solutions:

We understand no one warehouse or company in the diverse world of logistics is the same. That is why we offer bespoke solutions that scale to each business’s requirements.

Customer Support and Training:

We are the experts to guide you through this innovative technology. We offer assistance to everyone who needs it, explaining how everything works, recommending the ideal hardware and helping you scale up when you expand.

Start your journey with TEC-RFID

You can begin your journey into the new age of asset tracking and management in logistics by scheduling a free consultation with the team here at TEC-RFID. We will get to know your business and its needs and strategies how our solutions can help.

We also have a free guide for you to browse to get you up to speed on RFID technology.

Give us a call on 0844 870 7873 to book your consultation or reach to us via the button below.

Recommended RFID Equipment for Logistics Management

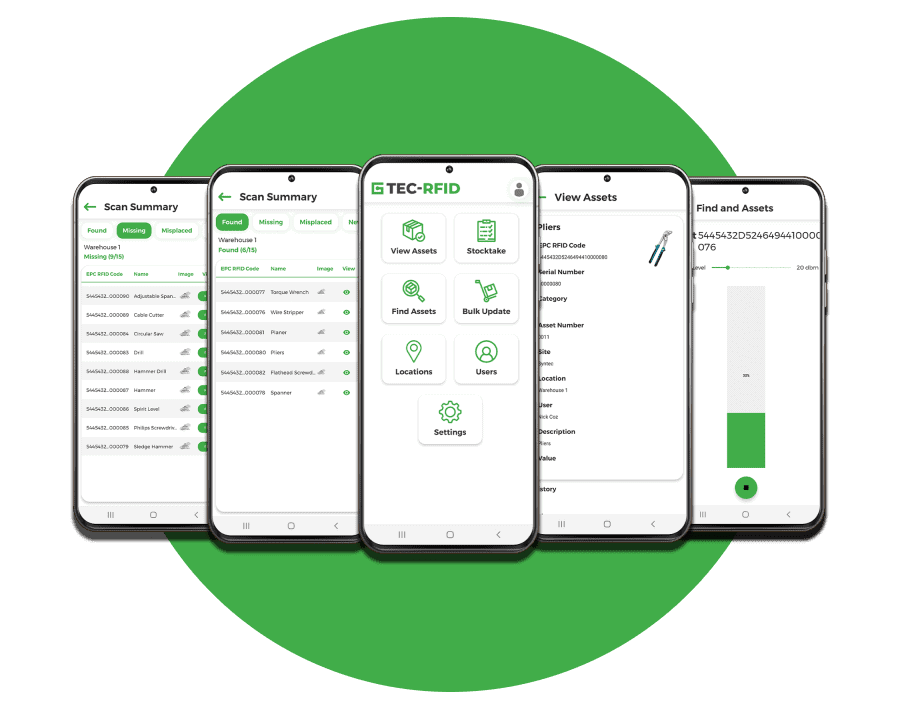

STOCKTAKING MADE SIMPLER WITH THE TEC-RFID ASSET MANAGEMENT APP

Stocktaking is made simple with the TEC-RFID Asset Management app, increasing not only the speed of your stocktake, but the accuracy too.