A sector that has a daily global impact on the economy, manufacturing alone amounted to almost 20% of the UK’s GDP in 2021. RFID in the manufacturing industry continues to play a pivotal role in improving elements in this vast sector that include everything from the supply chain and production to inventory management.

RFID in manufacturing offers greater flexibility and more streamlined day-to-day operations. With the ability to automate data collection, RFID tags act as a vital tool for both inventory management and quality control. Tags are often used to track changes, the status and health of items or even the equipment used to manufacture goods, offering greater control throughout the supply chain.

Using an RFID tracking system for manufacturing is a sure way to help your business thrive.

Benefits of RFID in Manufacturing

How Can RFID Technology Improve My Business?

Whether you’re looking to scale up your business, make your order processing more efficient or lower the number of stock issues throughout your supply chain, RFID is the smart solution.

No Physical Contact Needed:

Rather than hand-counting or scanning individual barcodes on items, RFID manufacturing tracking can instantaneously stocktake your entire business, even across multiple physical sites.

Variable Range:

Choose the range of the signal in the software and the tags you require, enabling you to check what’s inside an outgoing order without having to open it.

Enlarge and Curate Your Range:

Add new assets easily and quickly and use the time you save to research and curate solutions to further improve your business.

Track Assets at Every Stage:

Avoid discrepancies between actual stock amounts and system stock numbers by implementing an RFID tracking system so you can track where every business asset is located.

Stay On Top of Admin:

Assets can be grouped into categories, locations, by manufacturer and other customisable groups using our powerful and user-friendly software.

Scale Up with Your Existing Workforce:

Considerable efficiency savings and increased productivity mean you can grow your business at a measured pace and without a rapidly growing headcount.

Get the Edge on the Competition:

Maximise productivity and leave competitors behind with a robust, insightful and lightning-fast RFID manufacturing tracking system.

Why Do I Need RFID Technology?

As the industry continues to evolve, retaining efficiency to reduce costs is more important than ever. Ensuring that the supply chain is fully stocked throughout the entire manufacturing process of a product will help to keep orders on time and the likelihood of repeat business then increases.

A supply chain often faces problems such as container shortages, long-range logistics, congestion at shipping terminals and ports, labour shortages and increased fuel prices, further impacting efficiency. Using an RFID asset management system in your business can fix all of them.

End-to-End Supply Chain Visibility with RFID

End-to-end supply chain visibility refers to the ability to track and monitor products and materials throughout the entire supply chain, from the point of origin to the point of consumption. This includes tracking inventory levels, shipment status and product quality.

RFID technology provides a reliable and accurate way to track products and materials throughout the supply chain. RFID Tags can be attached to products or packaging, and the information can be read by RFID Readers at various points along the supply chain. This provides real-time visibility into inventory levels, shipment status and product quality. For example, RFID technology can be used to track the location and status of inventory in real-time, enabling manufacturers to optimise their inventory levels and reduce waste.

Our RFID Devices

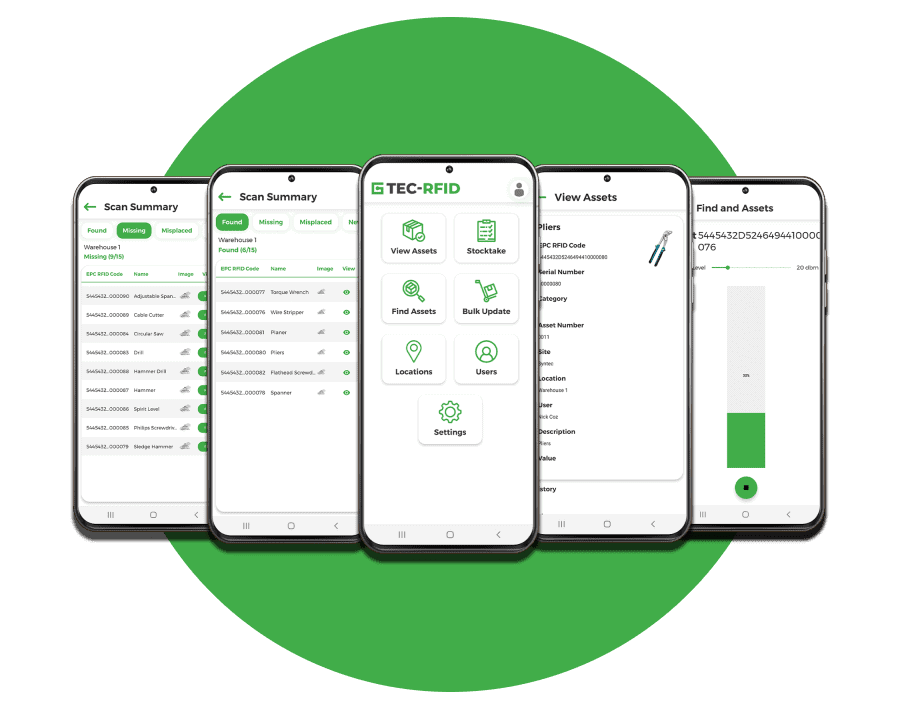

STOCKTAKING MADE SIMPLER WITH THE TEC-RFID ASSET MANAGEMENT APP

Stocktaking is made simple with the TEC-RFID Asset Management app, increasing not only the speed of your stocktake, but the accuracy too.