RFID technology is growing in popularity every day for the many benefits it holds. RFID technology can be used in many industries from Retail Sectors and Healthcare Services to Warehousing and many more! On this page, we will discuss the advantages of owning an RFID system and how it can improve your business and propel it to the next level.

Why Implement RFID?

Asset tracking and inventory management are the key uses of RFID for warehouses. RFID technology is proven to bring robust ROI. Let’s look at the keyways RFID is proven to provide almost 100% accuracy and safeguard valuable assets.

1. Save time

RFID technology is not cheap, but it’s worth the investment. When purchasing an RFID system, the first question many people have is: Will implementing an RFID System bring me a positive ROI?

The simple answer is yes. In 2018, GS1 UK released a report authored by Professor Adrian Beck of the University of Leicester on an RFID system trial from 10 major retailers. The study showed that together, they had a combined yearly sale of €94 billion and used at least 1.87 billion tags per year. Every single one of these companies reported a positive ROI from their trials.

2018 GS1 RFID Study

Labour Savings

A major drive of RFID systems is labour savings. According to Inbound Logistics, labour accounts for 65% of most warehouses’ operating budgets. Labour savings from RFID can quickly pay for the setup cost. The study from GS1 found that one company had savings equivalent to 4% of store staffing costs.

Lightning Fast Stocktaking

The real reason for staff savings is primarily from the dramatic improvement in ultra-fast read rates. According to software company Cybra, RFID systems improve read rates range from 200 items per hour to up to 12,000 items per hour. U.S. retailer Walmart trialled RFID technology in 12 stores and compared the results with 12 stores using barcoding for inventory.

Scanning a 10,000-item inventory with barcoding took 53 hours – with the RFID technology, it took just 2 hours. This meant a real-life read rate of 4,767 items per hour for RFID technology compared to 209 items for barcoding, a 96% reduction in counting time.

Barcoding

RFID

Reduction in stocktaking time

Does RFID technology produce a positive ROI? The results speak for themselves.

2. Improve accuracy

Inaccurate and out of date inventory results in losses through shrinkage and going out of stock of necessary items. RFID systems have been proven to dramatically increase the accuracy of inventory management by enabling more frequent stock counts and eliminating human error, such as missing barcodes or double scanning.

Cybra found that RFID technology improved inventory accuracy from an average of 65% to more than 95%. They also found that RFID technology can improve inventory accuracy to 99% and increase inventory visibility and availability from 2% to 20%. Shipping and picking accuracy was also improved by 80%, which can mean thousands of pounds in savings from chargeback penalties from delivering the wrong items.

Inventory Accuracy

65%

Barcoding

95%

RFID

The study by Professor Adrian Beck found that inventory accuracy was dramatically improved. For one company with 1.5 billion products, they found only 20 errors with tags, further highlighting the benefits of RFID. This also represents an error rate of 0.003% compared to a 1.5% error rate with barcodes. RFID technology increased accuracy to a 15% reduction in losses from shrinkage for one company.

Tag Errors

Inventory accuracy is a priority, and nothing brings better results than implementing an RFID system.

3. Locate items

Modern warehouses often occupy hundreds of thousands of square feet and contain thousands or millions of items in stock. Finding the right shipment at the right time can be extremely difficult. Attaching RFID tags to assets, pallets or products enables you to use a Real Time Location System (RTLS) to find any product or asset quickly and easily.

Zebra RFID system readers enable the use of the Zebra Motion works RTLS solution. With RTLS, you have greater visibility of your inventory and can quickly locate any item needed, maximising efficiency and reducing losses. One study of click-and-collect systems highlights the benefits of RFID as it found a huge improvement in the time taken to retrieve orders.

Real time location system

quickly and easily locate products

maximize efficiency

Click-and-Collect Orders

RFID Limitations

Metal and liquid-filled containers pose a problem when implementing an RFID system because they interfere with the radio waves. It’s important to take this into account when adopting an RFID system and to get the proper readers and tags to function properly in your environment.

Metal and Liquid

What's next?

Now that you’ve seen how RFID Technology can benefit your business, look closer at the specific applications, starting with asset management.

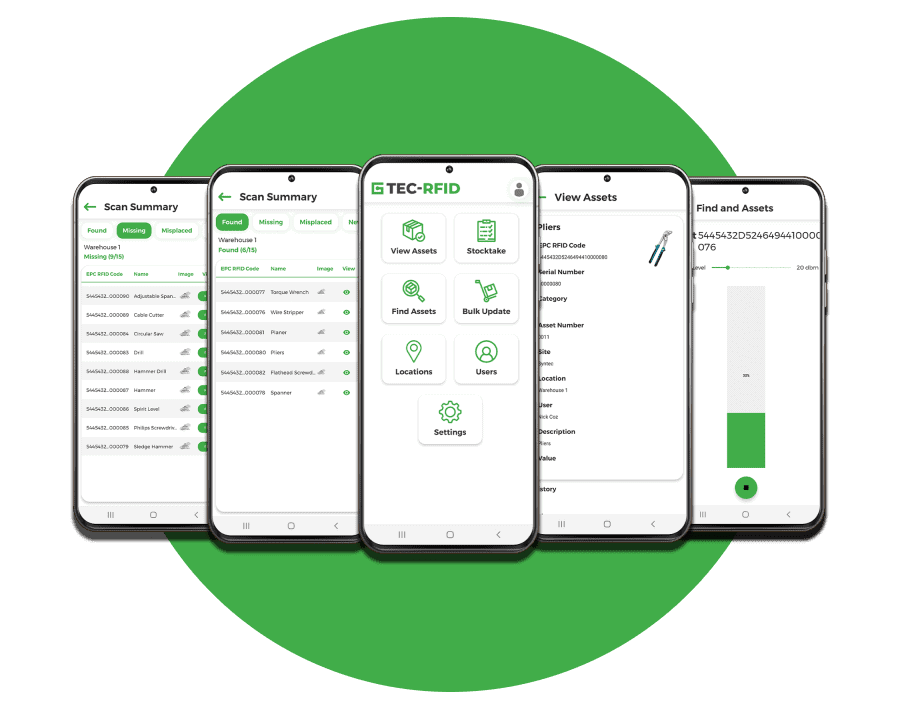

STOCKTAKING MADE SIMPLER WITH THE TEC-RFID ASSET MANAGEMENT APP