RFID or Radio Frequency Identification is a technology that uses radio waves to wirelessly identify, and track objects, animals or humans and it is comprised of two main components: tags and readers.

RFID technology is gaining in prominence due to its numerous advantages over traditional identification and tracking methods as it enables automatic and contactless data capture, which eliminates the need for manual scanning or line-of-sight interaction. It makes it faster, more accurate and less labour-intensive than barcode scanning or manual data entry. It can be used in a vast array of industries and applications.

Table of Contents

What is RFID Technology?

RFID tags, often attached to or embedded in objects, animals or even implanted in humans, contain a microchip and an antenna to transmit and receive data. The microchip stores data, such as a unique identifier or additional information, while the antenna allows the tag to communicate with RFID readers. RFID readers emit radio waves to communicate with the tags and retrieve information stored on them.

The reader then processes the data received and communicates it to a central system for further analysis or action. In logistics and supply chain management, RFID enables real-time tracking of goods, enhancing inventory management and reducing loss or theft. In healthcare, it is used for patient identification, medication tracking and asset management. There are vast opportunities for application in a plethora of other industries and settings.

How does RFID Technology work?

RFID technology operates based on the principle of electromagnetic coupling. When an RFID tag comes into the range of an RFID reader, the reader emits radio waves that power the tag’s microchip. The tag then modulates the radio waves and reflects them back to the reader, transmitting its unique identifier and any associated data. The reader captures this information and communicates it to a central system for processing and analysis. This simple, yet effective, mechanism allows for efficient and real-time identification and tracking of objects or individuals.

RFID Capabilities

read hundreds of tags in seconds

No need for line of sight

extreme durability

holds more data than barcodes

Read Range up to 15 metres

Tags can be rewritten

The History of RFID: From Invention to Modern Use

The roots of RFID technology can be traced back to WWII when radar systems were first developed. However, the concept of using radio waves for identification emerged later in the 1940s and gained more traction in the 1970s. It gained popularity for inventory management in the early 2000s. Over the years, RFID technology has evolved, becoming more sophisticated, affordable, and widely adopted. Today it has found extensive applications in various industries, revolutionising inventory management, supply chain logistics, access control and more.

What are the Different Types of RFID

There are many different types of RFID: low, high, and ultra-high frequency, active, passive, and semi-passive, and each type caters to different specific needs.

Active RFID tags have a power source and can transmit signals over longer distances, making them suitable for tracking assets or vehicles, and items of greater value. Passive RFID tags, on the other hand, rely on power from the reader and have shorter read ranges depending on the frequencies. They are commonly used for inventory management and retail applications.

For more information regarding the differences between Active and Passive RFID, check out our blog to gain more understanding of the topic.

Semi-passive tags combine some features of both active and passive tags and provide enhanced functionality for specific use cases. There are also three primary frequency ranges used for RFID transmissions – low frequency, high frequency, and ultra-high frequency.

Low Frequency 30 – 300kHz – Our low-frequency RFID readers have a read range of contact to 10cm and are used for access fobs, tracking animals and applications with a lot of liquids and metals. The most widely used frequencies in this band are 125 KHz and 134 KHz.

High Frequency 13.56MHZ – Our high-frequency RFID readers have a read range of contact to 30cm and are used mostly for consumer purposes such as access cards, contactless cards, library books and NFC technology found in phones. NFC is the most common use of HF RFID and uses the 13.56 MHz frequency.

Ultra-High Frequency 30 – 300 MHZ – Warehouses almost always use Ultra High Frequency (UHF) RFID readers for inventory and asset management. The most common frequency used in UHF RFID is 860 to 960 MHz. Passive RFID in this range can read tags at a range of up to 20m and Active RFID can read tags at a range of up to 300m.

Check out our Latest Blogs

RFID Asset Tracking – The Perfect Solution for Asset Management

RFID Asset Tracking – The Perfect Solution for Asset Management Table of Contents In today’s rapidly evolving business landscape, asset management has become more challenging …

8″ and 10″ Rugged Android Tablets with Integrated Barcode Scanner: Designed For Healthcare

Designed for Healthcare 8″ and 10″ Rugged Android Tablets with Integrated Barcode Scanner: Designed for Healthcare 8” and 10” Rugged Android Tablets with Integrated Barcode …

Introducing the Zebra TC22/TC27 Mobile Computer, New for 2023

Introducing the New Zebra TC22/TC27 Mobile Computers Introducing the latest generation of Zebra’s industry-leading range of mobile computers, at Tec-RFID. The new TC22 and TC27 …

Manage your Resources with RFID Asset Management

Manage your Resources with RFID Asset Management In today’s fast-paced and ever-more technology-driven world, efficient resource management is crucial for many businesses in a wide …

Introducing the Zebra ET40/ET45 Rugged Handheld Enterprise Tablets

Introducing the Zebra ET40/ET45 Rugged Handheld Enterprise Tablets Looking to upgrade your business’ mobile computing devices? Need a device that offers durability, reliability, and is …

Applications of RFID Technology in Industry and Daily Life

RFID technology has widespread applications across industries and everyday life. In manufacturing and logistics, RFID enables real-time inventory tracking, streamlines supply chain operations, and enhances product authentication. According to studies nearly three-quarters of orders have some form of error in the supply chain, whereas checking orders with an RFID inventory management software and scanners increased accuracy by 99%.

It also drastically reduces the time needed for stocktaking. For example, the US retailer Walmart found that scanning a 10,000-item inventory with barcoding took 53 hours, and with RFID it took just 2 – a 96% reduction in counting time.

RFID also finds applications in healthcare for patient tracking as well as asset tracking, tracking and locating essential equipment and supplies with a click of a button. In retail, it improves inventory management, reduces stock-outs or overstocking, and enables cashier-less checkout systems. For transportation, RFID can manage electronic toll collection and smart ticketing and in access control systems or large events, it can enable secure identification. The potential applications are almost limitless.

Active vs. Passive RFID

Passive RFID tags get their power from electromagnetic energy transmitted by the RFID reader. In Europe, they run on a frequency of 865-868MHz with a reading range of near contact to 20m. They are often used in supply chain tracking, Manufacturing, pharmaceuticals, electronic tolling, race timing, inventory tracking, and asset management.

However, Active RFID tags have their own battery and transmit their own signals. They run on a frequency range between 433MHz and 2.45GHz and have a reading range of 30-300m. These tags tend to be more expensive, so they are normally used for vehicle tracking, auto manufacturing, mining, construction and tracking valuable assets. BLE Beacons or Bluetooth Beacons are more affordable but less accurate form of active RFID.

Passive rfid

Read range: 0-25 m

Active rfid

Read range: 30-300 m

Visit our more in-depth guide about active and passive RFID, explaining the benefits and differences between the two.

Other RFID Accessories

Other RFID accessories are available, apart from tags, readers, and antennas, to enhance the functionality and performance of RFID technological systems. These include middleware software for data management and integration with existing systems, RFID printers for on-demand tag printing as well as encoders for programming tag data as well as tags and printable labels and mobile computers to interact with readers, whether handheld or fixed. There are also specialised enclosures and mounting options for readers and antennas to ensure proper installation and protection in various environments.

Future Developments in RFID Technology

RFID technology continues to evolve, paving the way for exciting advancements. The miniaturisation of tags, improved read range and accuracy as well as enhanced data security are areas of ongoing research and development. Furthermore, the integration of RFID with other technologies, such as sensors, blockchain and AI, holds immense potential for unlocking new applications and improving operational efficiency. As RFID technology progresses, it will contribute to the realisation of smarter cities, enhanced customer experiences and streamlined business processes.

Start your RFID Journey Today!

Frequently Asked Questions

RFID's ROI varies depending on the industry and application. It can deliver substantial benefits such as improved inventory accuracy, reduced labour costs, minimised stock-outs, and enhanced supply chain visibility. Assessing the ROI requires considering factors such as initial investment, operational savings and the impact on productivity and customer satisfaction.

RFID technology can be influenced by environmental factors such as metal interference, liquids, and radio frequency interference. These factors can affect read range, reliability, and overall system performance. Careful consideration of the environment and the selection of appropriate RFID components can help mitigate these challenges.

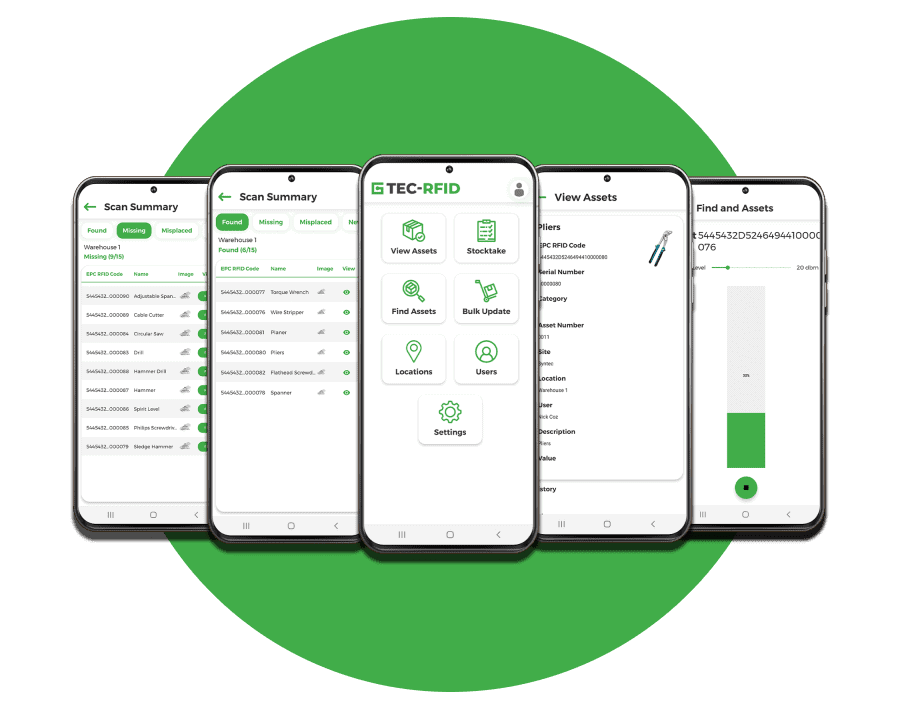

STOCKTAKING MADE SIMPLER WITH THE TEC-RFID ASSET MANAGEMENT APP

Stocktaking is made simple with the TEC-RFID Asset Management app, increasing not only the speed of your stocktake, but the accuracy too.